Screw Gauge

Screw gauge is a device which can measure very small lengths (or thickness) up to one – hundredth part of a millimeter. It can be used to measure diameter of a wire, thickness of a thin metal sheet, etc.

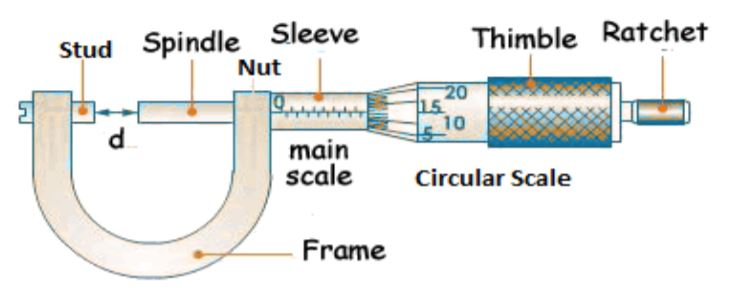

A Screw Gauge is shown here and its main parts are described below.

`text(Frame -)` It consists of U shaped metallic frame.To one side of this U frame there is a long hollow cylindrical tube with a nut inside it, the inner side of cylindrical nut contains a uniform thread cut in it.On the other side of U frame a fixed stud with a plane face is attached.

`text(Main scale -)` The extended portion of the nut , graduated in millimeters or half millimeters is called the main scale. It has a base line along the axis of the nut.

`text(Thimble -)` The hollow cylinder at the end of the screw is called thimble.

`text(Circular scale -)` The graduated head of the thimble is called circular scale (C.S.).The CS is generally divided into 50 or 100 equal divisions.

`text(Ratchet -)` The ratchet avoids undue tightening of the screw and helps in holding the object between the stud and the end of the screw.

A Screw Gauge is shown here and its main parts are described below.

`text(Frame -)` It consists of U shaped metallic frame.To one side of this U frame there is a long hollow cylindrical tube with a nut inside it, the inner side of cylindrical nut contains a uniform thread cut in it.On the other side of U frame a fixed stud with a plane face is attached.

`text(Main scale -)` The extended portion of the nut , graduated in millimeters or half millimeters is called the main scale. It has a base line along the axis of the nut.

`text(Thimble -)` The hollow cylinder at the end of the screw is called thimble.

`text(Circular scale -)` The graduated head of the thimble is called circular scale (C.S.).The CS is generally divided into 50 or 100 equal divisions.

`text(Ratchet -)` The ratchet avoids undue tightening of the screw and helps in holding the object between the stud and the end of the screw.