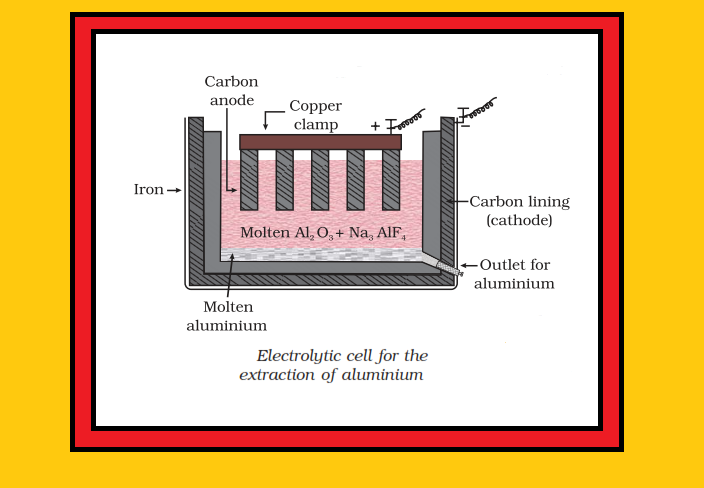

Extraction of Aluminium from alumina :

`=>` In the metallurgy of aluminium, purified `Al_2O_3` is mixed with `Na_3AlF_6` or `CaF_2` which lowers the melting point of the mix and brings conductivity.

`=>` The fused matrix is electrolysed.

● Cathode : Steel

● Anode : Graphite

`=>` The graphite anode is useful here for reduction to the metal.

`=>` The overall reaction may be taken as :

`2Al_2O_3 +3C → 4Al +3CO_2` .........(44)

`=>` This process of electrolysis is widely known as `text(Hall-Heroult)` process.

`=>` The electrolysis of the molten mass is carried out in an electrolytic cell using carbon electrodes.

`=>` The oxygen liberated at anode reacts with the carbon of anode producing `CO` and `CO_2`. This way for each kg of aluminium produced, about 0.5 kg of carbon anode is burnt away.

`=>` The electrolytic reactions are :

Cathode : `Al^(3+)` (melt) `+3 e^(-) → Al (l)` .......(45)

Anode : `C(s) + O^(2-) ` (melt) `→ CO (g) + 2e^(-)` ......(46)

`C(s) +2O^(2-) ` (melt) `→ CO_2 (g) +4e^(-)` .........(47)

`=>` The fused matrix is electrolysed.

● Cathode : Steel

● Anode : Graphite

`=>` The graphite anode is useful here for reduction to the metal.

`=>` The overall reaction may be taken as :

`2Al_2O_3 +3C → 4Al +3CO_2` .........(44)

`=>` This process of electrolysis is widely known as `text(Hall-Heroult)` process.

`=>` The electrolysis of the molten mass is carried out in an electrolytic cell using carbon electrodes.

`=>` The oxygen liberated at anode reacts with the carbon of anode producing `CO` and `CO_2`. This way for each kg of aluminium produced, about 0.5 kg of carbon anode is burnt away.

`=>` The electrolytic reactions are :

Cathode : `Al^(3+)` (melt) `+3 e^(-) → Al (l)` .......(45)

Anode : `C(s) + O^(2-) ` (melt) `→ CO (g) + 2e^(-)` ......(46)

`C(s) +2O^(2-) ` (melt) `→ CO_2 (g) +4e^(-)` .........(47)