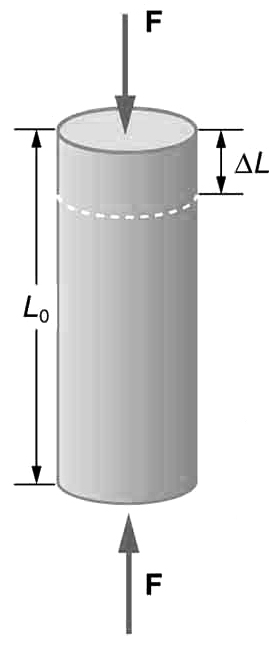

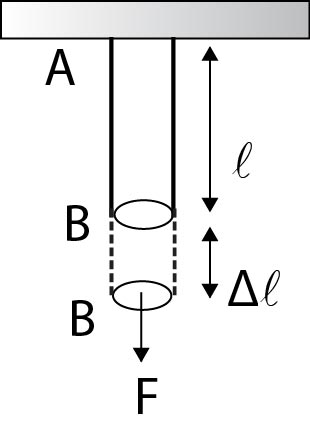

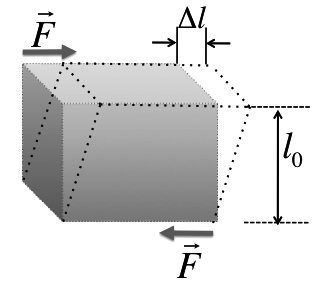

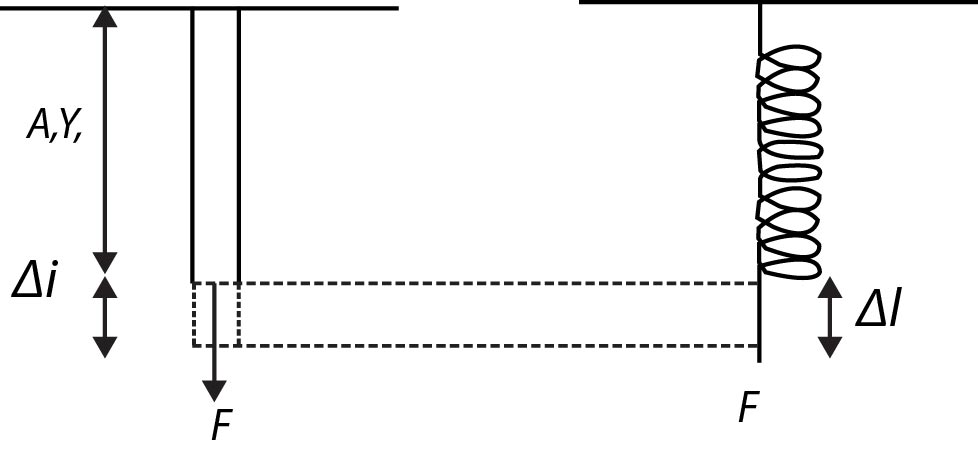

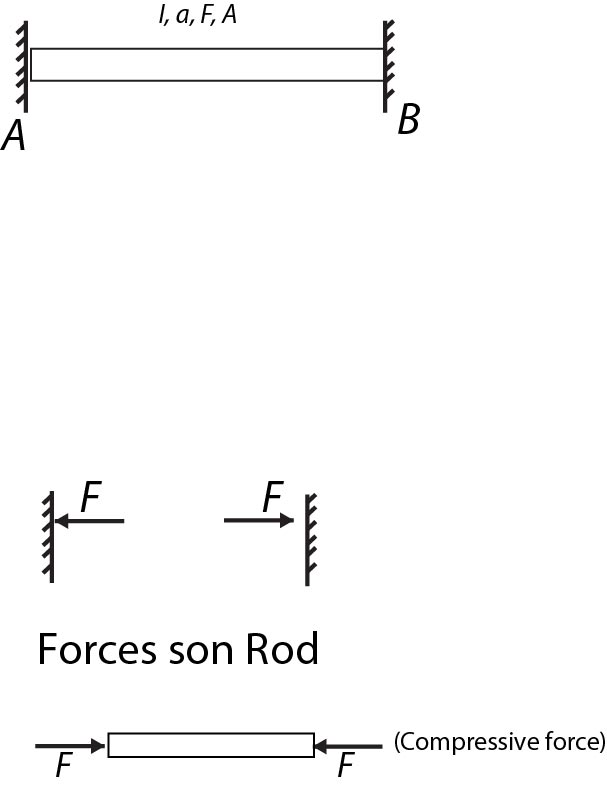

Tensile Stress:

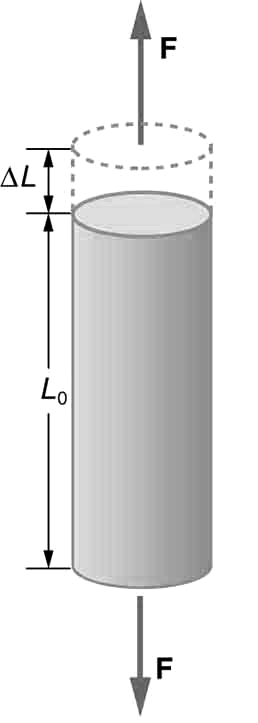

If there is an increase in dimension or length of body in the direction of force applied, the stress is called Tensile stress.

Example A solid cylinder is stretched by two equal forces applied normal to its cross-section.

Example A solid cylinder is stretched by two equal forces applied normal to its cross-section.