Types of Addition Polymerisation :

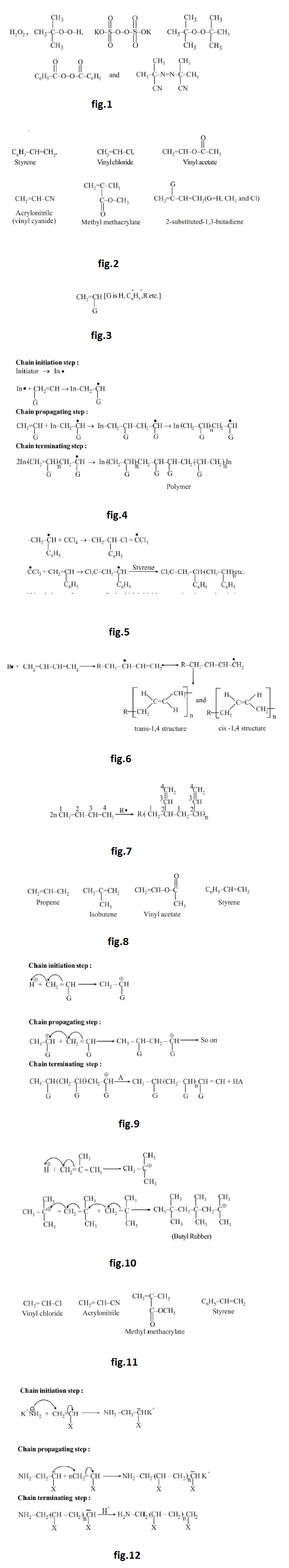

(A) `text(Radical Polymerisation :)` (i) Radical polymerisaiton takes place in the presence of radical initiators. The radical initiator may be any of the following : See fig.1.

(ii) Reaction intermediate of radical polymerizaiton is a free radical.

(iii) Radical polymerization has more chance for those monomers whose free radicals are more stable. Examples are : See fig.2.

(iv) Radical polymer has linear as well as branched chain structure.

Most of the commercial addition polymers are vinyl polymers obtained from alkenes and their derivatives. See fig.3.

This type of polymerisation is preformed by heating the monomer with only a very small amount of the initiator or by exposing the monomer to light. The general mode of radical polymerisation of vinyl monomers is depicted below : See fig.4.

In vinylic polymerisation, various other reaction of free radicals with some other compounds present may compete with the parent addition chain reactions. One such reaction takes place with molecules that can react with the growing chain to interrupt the further growth. This leads to the lowering of the average molecular mass of the polymer. Such reagents are called as chain transfer agents and include `C Cl_4`, `CBr_4` etc.

For example, in the presence of `C Cl_4`, styrene polymerises to form plystyrene of a lower average molecular mass which also contains some chlorine what happens here is that growing polystyrene radical which normally would add on a monomer reacts with the chain transfer agent to end the original chain and produces a new radical. The latter initiates a new polymerisation chain and thereby forms a new polymer as depicted below. See fig.5.

lf the chain transfer agent a radical, which is highly unreactive, the reaction chain gets terminated such a compound thus inhibits or arrests polymerisation. Many amines, phenols, quinones etc. act as inhibitors. So, even traces of certain impurities, which can act as chain transfer agent or an inhibitor can interfere with the original polymerisarion chain reaction. Hence, the monomers could be free from such inhibitors.

In case the alkene is a diene, the following kinds of polymerisation is possible :

(a) `1, 4-` `text(polymerisaiton :)` When the polymerisation takes place at `C`, and `C_4` of butadiene, an unbranched polymer is formed. This product is different from that formed from an alkene having a double bond, which at each of its carbons is substituted by different groups and hence can exist either as trans-polybutadiene or cis-polybutadiene or a mixture as shown below See fig.6.

(b) `1, 2-` `text(Polymerisation :)` Alternatively, `1, 3`-butadiene can undergo polymerisaiton at `C_1` and `C_2` to yield the polymeric product, polyvinly polythene. See fig.7.

The double bonds in these initial polymers can be linked by further treatment with chemicals to modify the properties of the polymers. These reactions form the basis of the formation of rubber.

(B) `text(Cationic Polymerisation :)`

(i) Polymerisation which is initiated by an electrophile is known as cationic polymerisation.

(ii) Reaction intermediate of cationic polymerisation is a carbocation.

(iii) Carbocations can undergo rearrangement leading to the formation of a more stable carbocation.

(iv) The electrophile commonly used for initiation is `BF_3*C Et_2`

(v) Monomers that are best able to undergo polymerisation by a cationic mechanism are those with electron- donating substituents that can stabilise the carbocation. Some examples are : See fig.8.

(vi) It is terminated by a base.

Thus, when the initiator is cationic in nature, it would generate a cationic intermediate on addition to the double bond for propagating the addition chain process and is termed as cationic addition polymerisation. The process is initiated by an acid. The stages of polymerisation are depicted below : See fig.9.

Cationic polymerisation is facilitated in monomers containing electron-releasing groups. Thus, isobutylene undergoes cationic polymerisation easily as it has two electron releasing `-CH_3` groups that will stabilize the intermediate carbocation. See fig.10.

(C) Anionic Polymerisation :

(i) Anionic polymerisation takes place in the presence of base or nucleopile, which is initiator in this polymerizarion.

(ii) Reaction intermediate in propagation steps are carboanion.

(iii) The suitable initiator can be `NaNH_2` or `RLi`.

(iv) Those monomers undergo anionic polymerisation reaction whose anion is stable.

Example of monomers are : See fig.11.

(v) Anionic polymerisation always gives linear polymer.

(vi) Anionic polymerisation terminated by an acid.

The formation of polystyrene from styrene in the presence of potassium amide is an important example of this category of polymerisarion. The mode of anionic polymerisarion is depicted below : See fig.12.

(D) `text(Ziegler- Natta polymerisation)` :

(i) Addition polymerisation which takes place in the presence of Ziegler- Natta catalyst `[(C_2H_5)_3AI` and `TiCI_4]` is known as Ziegler- Natta polymerisation or coordination polymersation.

(ii) Ziegler- Natta polymerisation always gives linear, stereo-regular polymers.

(iii) Ziegler- Natta catalyst revolutionised the field ofpolymerchemisl:!y because they allow the synthesis of stronger and stiffer polymers (due to linear geometry) that have greater resistance to cracking and heat. High density polyethylene is prepared using a Ziegler- Natta catalyst.

(ii) Reaction intermediate of radical polymerizaiton is a free radical.

(iii) Radical polymerization has more chance for those monomers whose free radicals are more stable. Examples are : See fig.2.

(iv) Radical polymer has linear as well as branched chain structure.

Most of the commercial addition polymers are vinyl polymers obtained from alkenes and their derivatives. See fig.3.

This type of polymerisation is preformed by heating the monomer with only a very small amount of the initiator or by exposing the monomer to light. The general mode of radical polymerisation of vinyl monomers is depicted below : See fig.4.

In vinylic polymerisation, various other reaction of free radicals with some other compounds present may compete with the parent addition chain reactions. One such reaction takes place with molecules that can react with the growing chain to interrupt the further growth. This leads to the lowering of the average molecular mass of the polymer. Such reagents are called as chain transfer agents and include `C Cl_4`, `CBr_4` etc.

For example, in the presence of `C Cl_4`, styrene polymerises to form plystyrene of a lower average molecular mass which also contains some chlorine what happens here is that growing polystyrene radical which normally would add on a monomer reacts with the chain transfer agent to end the original chain and produces a new radical. The latter initiates a new polymerisation chain and thereby forms a new polymer as depicted below. See fig.5.

lf the chain transfer agent a radical, which is highly unreactive, the reaction chain gets terminated such a compound thus inhibits or arrests polymerisation. Many amines, phenols, quinones etc. act as inhibitors. So, even traces of certain impurities, which can act as chain transfer agent or an inhibitor can interfere with the original polymerisarion chain reaction. Hence, the monomers could be free from such inhibitors.

In case the alkene is a diene, the following kinds of polymerisation is possible :

(a) `1, 4-` `text(polymerisaiton :)` When the polymerisation takes place at `C`, and `C_4` of butadiene, an unbranched polymer is formed. This product is different from that formed from an alkene having a double bond, which at each of its carbons is substituted by different groups and hence can exist either as trans-polybutadiene or cis-polybutadiene or a mixture as shown below See fig.6.

(b) `1, 2-` `text(Polymerisation :)` Alternatively, `1, 3`-butadiene can undergo polymerisaiton at `C_1` and `C_2` to yield the polymeric product, polyvinly polythene. See fig.7.

The double bonds in these initial polymers can be linked by further treatment with chemicals to modify the properties of the polymers. These reactions form the basis of the formation of rubber.

(B) `text(Cationic Polymerisation :)`

(i) Polymerisation which is initiated by an electrophile is known as cationic polymerisation.

(ii) Reaction intermediate of cationic polymerisation is a carbocation.

(iii) Carbocations can undergo rearrangement leading to the formation of a more stable carbocation.

(iv) The electrophile commonly used for initiation is `BF_3*C Et_2`

(v) Monomers that are best able to undergo polymerisation by a cationic mechanism are those with electron- donating substituents that can stabilise the carbocation. Some examples are : See fig.8.

(vi) It is terminated by a base.

Thus, when the initiator is cationic in nature, it would generate a cationic intermediate on addition to the double bond for propagating the addition chain process and is termed as cationic addition polymerisation. The process is initiated by an acid. The stages of polymerisation are depicted below : See fig.9.

Cationic polymerisation is facilitated in monomers containing electron-releasing groups. Thus, isobutylene undergoes cationic polymerisation easily as it has two electron releasing `-CH_3` groups that will stabilize the intermediate carbocation. See fig.10.

(C) Anionic Polymerisation :

(i) Anionic polymerisation takes place in the presence of base or nucleopile, which is initiator in this polymerizarion.

(ii) Reaction intermediate in propagation steps are carboanion.

(iii) The suitable initiator can be `NaNH_2` or `RLi`.

(iv) Those monomers undergo anionic polymerisation reaction whose anion is stable.

Example of monomers are : See fig.11.

(v) Anionic polymerisation always gives linear polymer.

(vi) Anionic polymerisation terminated by an acid.

The formation of polystyrene from styrene in the presence of potassium amide is an important example of this category of polymerisarion. The mode of anionic polymerisarion is depicted below : See fig.12.

(D) `text(Ziegler- Natta polymerisation)` :

(i) Addition polymerisation which takes place in the presence of Ziegler- Natta catalyst `[(C_2H_5)_3AI` and `TiCI_4]` is known as Ziegler- Natta polymerisation or coordination polymersation.

(ii) Ziegler- Natta polymerisation always gives linear, stereo-regular polymers.

(iii) Ziegler- Natta catalyst revolutionised the field ofpolymerchemisl:!y because they allow the synthesis of stronger and stiffer polymers (due to linear geometry) that have greater resistance to cracking and heat. High density polyethylene is prepared using a Ziegler- Natta catalyst.